Common issues and how to prevent them

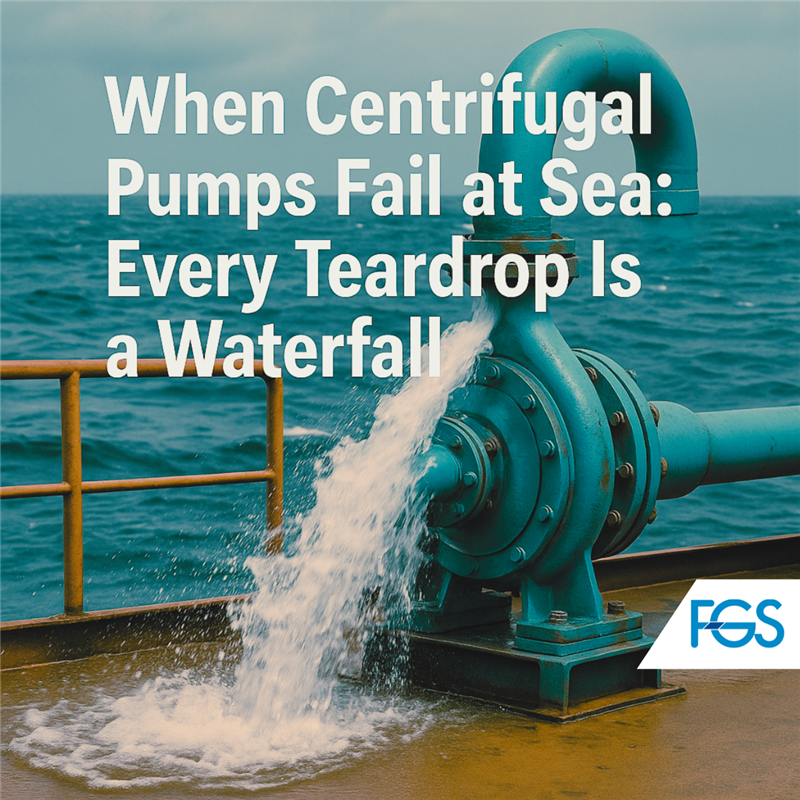

From bilge to ballast, firefighting to fuel transfer, centrifugal pump are the hidden workhorses behind a vessel's functionality.

But what happens when a centrifugal pump fails in the middle of a voyage? Spoiler alert: nothing good.

That's why recognising early signs of wear and knowing what causes failure is critical for every Chief Engineer overseeing maritime assets. This proactive approach ensures that the Captain can rest easy, knowing potential failures are being monitored and addressed.

Here's a closer look at the most frequent centrifugal pump failures observed in the marine industry and how to prevent them before they impact your uptime (or your bottom line).

1. The Silent Saboteur: Defective Mechanical Seals

Defective seals are the maritime equivalent of a slow leak in a diving suit—quiet, subtle, and devastating over time. They're one of the most common sources of flow losses and can quickly escalate into motor failure if left unchecked.

In marine environments, where saltwater corrosion and fluctuating pressures are the norm, seal integrity is constantly under siege. If the seal fails, the pump loses efficiency, and leaked fluid can damage adjacent systems or accelerate bearing wear.

Prevention Tip:

Routine inspection of the seal housing and scheduled seal replacement based on operating hours and environmental conditions can dramatically extend your pump's lifespan.

2. Turbine Breakage: When Things Go South—Fast

While less frequent, turbine breakage is a catastrophic failure that brings operations to a grinding halt. It's often caused by mechanical stress, sudden pressure surges, or cavitation—a phenomenon all too common in marine pumping systems.

Symptoms often include unusual vibrations or knocking sounds (yes, your pump may be trying to tell you something). Left unresolved, turbine failure can trigger a domino effect, damaging the shaft, bearings, and even the motor.

Prevention Tip:

Avoid running the pump dry or under erratic flow conditions. Monitor for cavitation and install protective devices like pressure relief valves or vibration sensors. Trust us—your future self will thank you.

3. End-of-Life Bearings: Death by Friction

Even the best-designed pumps can't outrun time. Motor bearings will eventually wear out, especially under continuous operation and high load conditions typical in maritime systems.

When bearings degrade, you might hear high-pitched whining or feel excessive heat around the motor housing. Ignoring these signs risks not only a failed pump but also motor seizure or even onboard fire hazards.

Prevention Tip:

Bearings should be lubricated at manufacturer-recommended intervals and replaced before their estimated service life ends. Intelligent maintenance scheduling beats emergency procurement every time.

Why Regular Inspection Matters

It's easy to get complacent when everything is "running fine." But like any industrial equipment, centrifugal pumps thrive on attention. Regular checks on flow rates, noise levels, and temperature can provide clues before minor issues become major failures.

And let's be honest: no Technical Director enjoys unplanned downtime, and no purchasing manager likes last-minute part orders at premium prices. Prevention is not just smarter—it's more cost-effective.

Let FGS Be Your Partner in Performance

At FGS, we don't just supply centrifugal pumps—we provide peace of mind. With decades of experience designing, maintaining, and replacing marine and industrial pumps, we speak the reliability language.

Our team can assist in preventive maintenance planning, urgent troubleshooting, or custom replacement solutions—whether you're managing a fleet of offshore vessels or a single-engine room in port.

Want to learn more? Get in touch and keep your operations sailing smoothly.

🚢 Stay on course. Think ahead. Trust expertise. Trust FGS.